Ceramic is a beautiful yet unforgiving material. One wrong move can lead to cracks, chips, or wasted pieces. That is why professionals and serious hobbyists are turning to advanced cutting methods that offer precision without sacrificing speed. Among these, the Diamond Wire Loop Saw has become a standout solution for anyone seeking clean edges and complex designs. When paired with modern techniques like Diamond Wire Cutting: Custom Ceramic Shapes Made Easy, it opens up new creative possibilities for ceramic artists, tile manufacturers, and industrial fabricators alike.

Understanding the Art of Ceramic Cutting

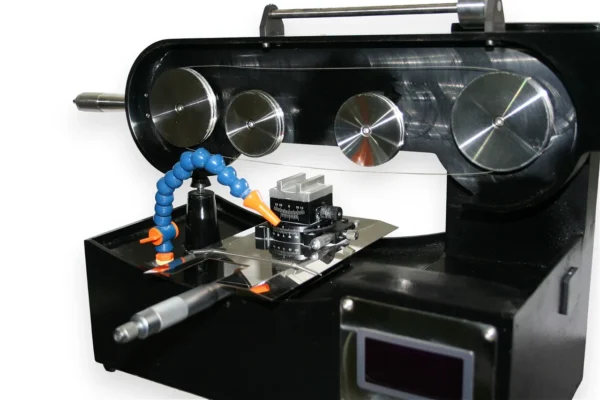

Ceramic cutting has always required a balance between strength and finesse. Traditional blades often struggle with delicate surfaces, especially when working on intricate patterns or curved profiles. The Diamond Wire Loop Saw changes that dynamic by replacing rigid edges with a flexible wire embedded with industrial diamonds. This allows smoother movement through ceramic materials while maintaining impressive accuracy.

As more workshops adopt Diamond Wire Cutting: Custom Ceramic Shapes Made Easy, the focus has shifted from simple straight cuts to fully customized forms. Whether it is decorative tiles, artistic sculptures, or technical ceramic components, the demand for flawless finishes continues to grow.

Why the Diamond Wire Loop Saw Stands Out

The Diamond Wire Loop Saw is designed to glide through ceramic with minimal resistance. Its looped wire structure distributes pressure evenly, reducing the risk of micro-fractures that can weaken the final piece. Unlike conventional saws, it does not rely on aggressive force. Instead, it delivers consistent cutting through precision and control.

This is exactly why Diamond Wire Cutting: Custom Ceramic Shapes Made Easy has become such a popular approach in modern ceramic workshops. The flexibility of the wire makes it possible to achieve curves, tight angles, and detailed contours that would be nearly impossible with standard tools. For anyone aiming to elevate their craftsmanship, the Diamond Wire Loop Saw is a game changer.

Precision Meets Creativity in Custom Ceramic Shapes

One of the most exciting aspects of Diamond Wire Cutting: Custom Ceramic Shapes Made Easy is how it empowers creativity. Ceramic designers are no longer limited by straight lines or basic geometry. With a Diamond Wire Loop Saw, they can explore organic forms, artistic patterns, and unique textures while still maintaining structural integrity.

This technique is not just about aesthetics. In technical and industrial applications, custom ceramic shapes are often required for insulation, electronics, and mechanical components. Here, accuracy is critical. The Diamond Wire Loop Saw ensures every cut meets tight tolerances, making Diamond Wire Cutting: Custom Ceramic Shapes Made Easy both a creative and practical solution.

The Role of Ensolltools in Modern Ceramic Cutting

When it comes to reliable cutting tools, Ensolltools has built a strong reputation for quality and innovation. Their Diamond Wire Loop Saw systems are engineered to deliver durability, smooth operation, and consistent results across a wide range of ceramic materials.

What sets Ensolltools apart is their understanding of real-world workshop needs. They design tools that are easy to handle, adaptable to different setups, and capable of supporting advanced methods like Diamond Wire Cutting: Custom Ceramic Shapes Made Easy. For professionals who demand performance without constant maintenance, Ensolltools provides solutions that stand the test of time.

By choosing Ensolltools, users gain access not only to premium equipment but also to a brand that stays aligned with evolving ceramic cutting technologies.

Comparing Traditional Methods with Diamond Wire Technology

Traditional ceramic cutting tools often rely on rigid diamond blades or abrasive discs. While these still have their place, they can struggle with detailed work and may generate excessive heat or vibration. The Diamond Wire Loop Saw, on the other hand, offers smoother operation and better control, especially for complex cuts.

This is why many professionals are shifting toward Diamond Wire Cutting: Custom Ceramic Shapes Made Easy as their preferred method. It reduces material waste, lowers the risk of damage, and enhances overall efficiency. Over time, the improved accuracy can also translate into cost savings, making the Diamond Wire Loop Saw a smart investment for both small studios and large-scale operations.

Getting the Best Results with the Right Technique

To fully benefit from a Diamond Wire Loop Saw, proper technique and setup are essential. Maintaining steady tension, using adequate cooling, and allowing the wire to do the work rather than forcing the cut can make a noticeable difference in results. With practice, operators quickly learn how Diamond Wire Cutting: Custom Ceramic Shapes Made Easy becomes not just a method, but a refined skill.

Ensolltools supports this learning curve by offering tools that are user-friendly and built for consistency, helping users achieve professional results even on demanding projects.

Conclusion: Perfect Cuts Start with the Right Tool

In the world of ceramic fabrication, precision is everything. The Diamond Wire Loop Saw has proven itself as a powerful tool for achieving smooth edges, detailed designs, and reliable performance. When combined with the approach of Diamond Wire Cutting: Custom Ceramic Shapes Made Easy, it transforms how ceramics are shaped and finished.

With trusted brands like Ensolltools leading the way, professionals now have access to cutting solutions that match both their technical demands and creative ambitions. If your goal is to achieve perfect cuts for ceramic, investing in a Diamond Wire Loop Saw is not just a choice, it is a step toward excellence.